Diamond Brite Metals Hemming and Seaming In Metal Processing

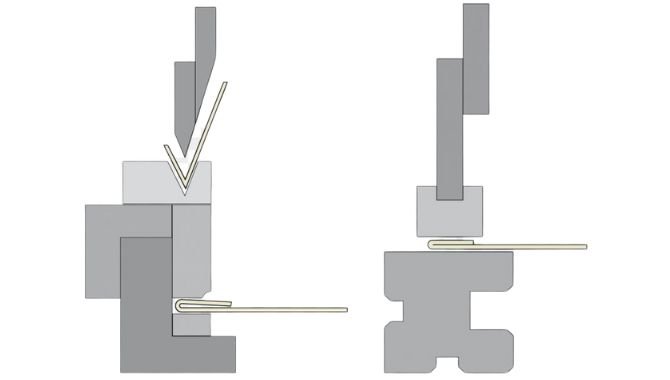

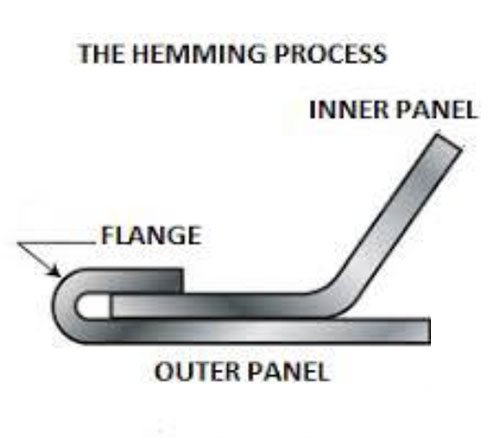

Hemming and seaming are two similar metalworking processes, where a sheet of metal edge is rolled over and over onto itself until it achieves a tight fit. In hemming, the edge is rolled to itself, while in seaming the edges of two materials are joined. Hems are typically used to reinforce edges, improve the appearance, connect parts together, and to hide burrs and rough edges. Seams are mainly used in the food industry for canned goods, on amusement park rides, and in the automobile industry. He

Hemming and seaming are essentially similar process, where sheet metal edges are rolled over to achieve better appearance and tight fits. Find out more.

Sheet Metal Works MCQ [Free PDF] - Objective Question Answer for

Week 2:- BiW Fixture Basics Challenge

Diamond Brite Metals

Diamond Brite Metals' Reference Guide for Surface Finishes

100 3003-H22 TREAD BRITE SHEET ASTM A786

D'source Hemming and Seaming, Sheet Metal Joinery

Diamond Brite Metals

Applied Sciences April-2 2020 - Browse Articles

Diamond Brite Metals Difference Between Passivation vs

What factors influence formability in metal forming? - Quora

David Ortegel Steven Neidigk Tim Ngo Jason Maestas - ppt video