Chrome Plating Process Diagram - How We Chrome Plate Wheels & Parts

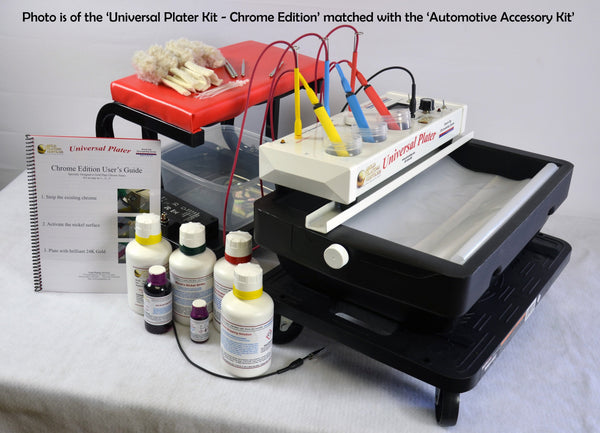

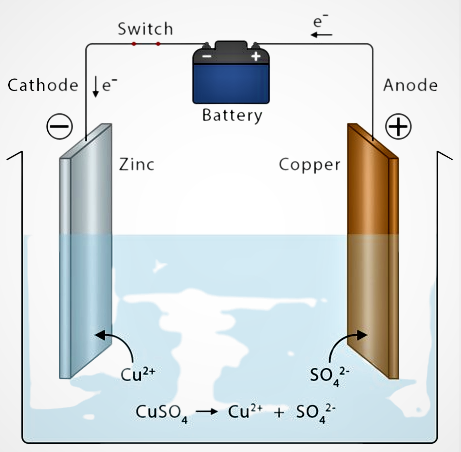

Take a look at our Chrome Plating process diagram step-by-step. The chrome plating process is a procedure of applying a thin layer of chromium onto a substrate (metal or alloy) through an electroplating procedure.

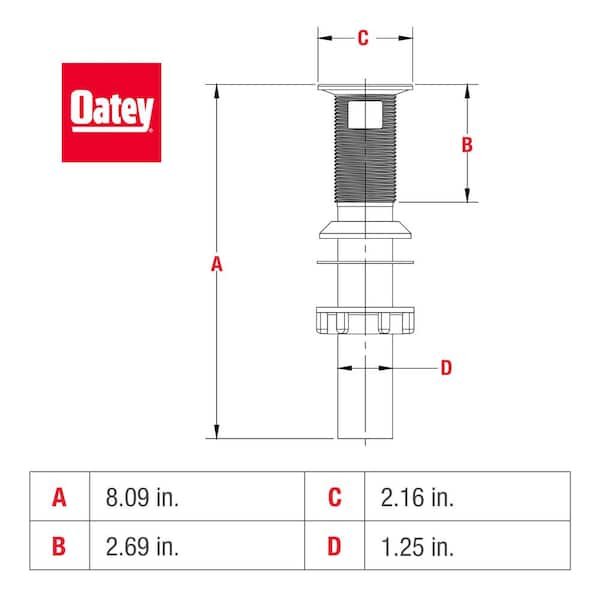

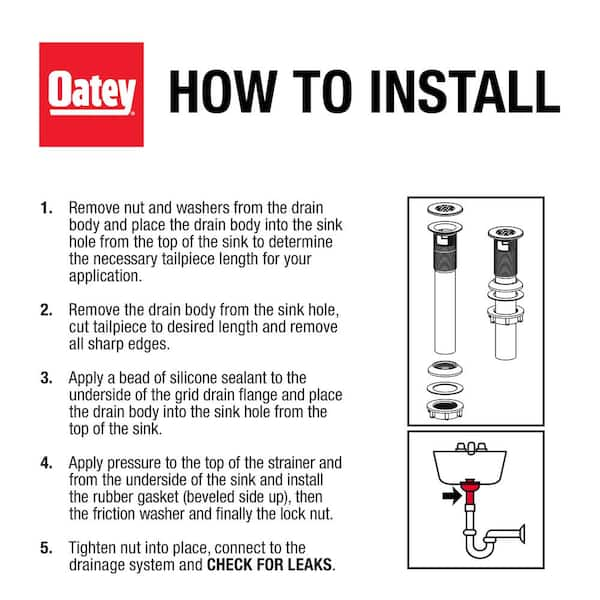

Oatey Designline Chrome-Plated Plastic Grid Drain with Overflow HDC9690 - The Home Depot

Chrome Plating Process Diagram - How We Chrome Plate Wheels & Parts

Coatings, Free Full-Text

Carbon Steel Simplex Plate Wheels Roller Chain Sprocket Gear - China Gear, Sprocket

Replace your old center caps and improve the look of your auto, truck or trailer with TYK Industries' high quality chrome plated cold forged steel center cap. Easy to install, this push-through cap fits a 4.25 inch center bore and is 4.25 inches tall. The center bore is the size of the hole in the center of the wheel that the cap fits through. The center bore (also known as spigot size) is the diameter of this hole. See pictures for dimensions represented visually.

TYK Industries Chrome Push Through Center Cap for Auto or Trailer Wheel Rims - 1 / Chrome / 2.95

Oatey Designline Chrome-Plated Plastic Grid Drain with Overflow HDC9690 - The Home Depot

Electroplating process with all variables - g groups

Hydraulic Cylinder Rod Hard Chrome Plating Explained.

Chrome Plating Wheelsmith Wheels