Silver Soldering for Jewelry Making

Silver Soldering for Jewelry MakingInstructor: Dwight H. BennettSaturday, July 18th9 am-4 pm with one hour for lunch This is perhaps the most fundamental class amongst all the classes in jewelry making and metalsmithing.It all revolves around the “hard silver solders,” that is, solders that flow between 1325°F and 1490°F which is just barely lower than the melting point of sterling silver’s 1640°F.In this six-hour class, you will learn seven basic necessities to achieve a good, high-quality solder seam or joint: That the surfaces to be soldered together must fit well with the least bit of a gap; That the metal surfaces to be joined must be clean of all oxidation and contaminants; That the surfaces are adequately fluxed while under the torch’s flame. Heated flux turns into an impenetrable “glass” barrier that keeps oxygen from contacting the metal surfaces while the solder flows through the flux and fuses to the metal; That heating the metal too quickly makes all your solder chips pop all over the place! As flux is heated, it boils and expands, pushing the joints apart slightly. But continuing to heat the joint will allow the flux to “relax,” which allows the joint to come together again; That solder will instantly fuse to the metal that has obtained the temperature above the melting point of the solder; And that all surfaces to be soldered must arrive to the temperature above the melting point of the solder simultaneously, or the solder will “jump” to the surface that has arrived to that temperature first. We will learn to use a variety of soldering torches, and how to use appropriate flames from those torches for soldering, brazing and annealing metal.PLEASE NOTE: This class is for Beginners or the more advanced students wishing to improve their soldering skills.

Silver Soldering for Jewelry MakingInstructor: Dwight H. BennettSaturday, July 18th9 am-4 pm with one hour for lunch This is perhaps the most fundamental class amongst all the classes in jewelry making and metalsmithing.It all revolves around the “hard silver solders,” that is, solders that flow between 1325°F and 1490°F which is just barely lower than the melting point of sterling silver’s 1640°F.In this six-hour class, you will learn seven basic necessities to achieve a good, high-quality solder seam or joint: That the surfaces to be soldered together must fit well with the least bit of a gap; That the metal surfaces to be joined must be clean of all oxidation and contaminants; That the surfaces are adequately fluxed while under the torch’s flame. Heated flux turns into an impenetrable “glass” barrier that keeps oxygen from contacting the metal surfaces while the solder flows through the flux and fuses to the metal; That heating the metal too quickly makes all your solder chips pop all over the place! As flux is heated, it boils and expands, pushing the joints apart slightly. But continuing to heat the joint will allow the flux to “relax,” which allows the joint to come together again; That solder will instantly fuse to the metal that has obtained the temperature above the melting point of the solder; And that all surfaces to be soldered must arrive to the temperature above the melting point of the solder simultaneously, or the solder will “jump” to the surface that has arrived to that temperature first. We will learn to use a variety of soldering torches, and how to use appropriate flames from those torches for soldering, brazing and annealing metal.PLEASE NOTE: This class is for Beginners or the more advanced students wishing to improve their soldering skills.

Nickel Silver Triangle 25.5mm 20g for Stamping Jewelry Making Texturing Soldering Blanks - Supply Diva

10 Tools You Need to Solder Sterling Silver — Make Silver Jewelry

Saturday, August 29, 20209am to 4pm with one hour off for lunch. This is a fundamental class for the fields of jewelry making and metalsmithing.This

Silver Soldering for Jewelry Making August 29th | WashingtonCollegeAc.

How to pick the best solder and flux for jewelry soldering?

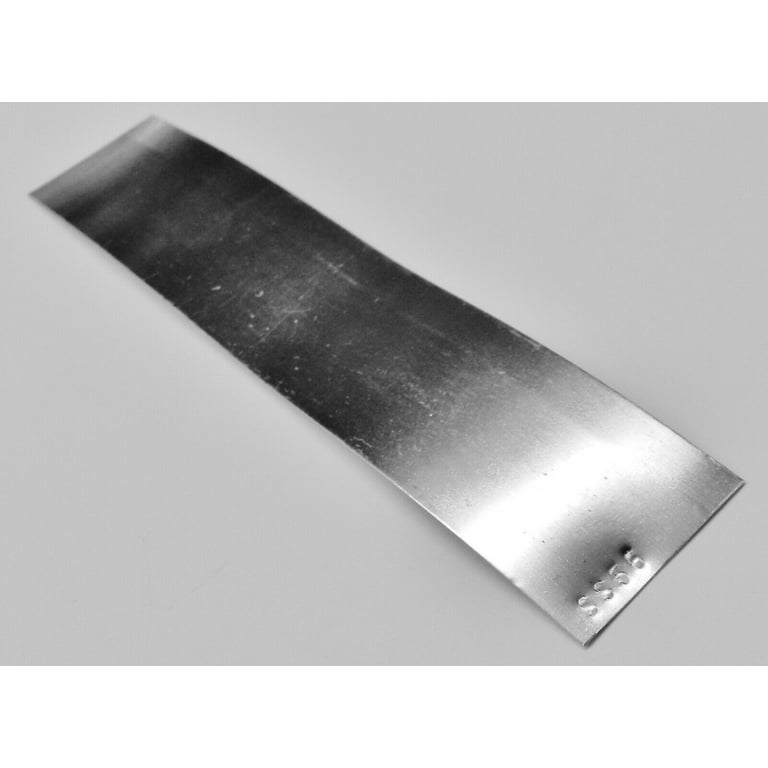

Silver Solder Sheet 5 DWT Medium Repair Solder Jewelry Making Soldering Tool USA - Findings Outlet

How To Easily Copper Plate Silver Solder Copper wire jewelry, Metal jewelry making, Soldering jewelry

Hello! Novice here, wondering is there a way to strengthen soft soldering jewelry ? Thorns are a bit fragile and I want to know if there's a work around . Planning to

Sadnyy 2 mm 150 Pcs Gold Solder Silver for Jewelry 14K Including E M H Easy Welding DIY Making Repair Electronic Soldering 1 at MechanicSurplus.com

Soldering (Beginner) [Class in NYC] @ Bushwick Jewelry Casting

Package Contents: You will receive 4.5 gram of silver solder precut chips and each silver chip measures about 1x1 mm / 0.039x0.039 inch for jewelry

Silver Solder Precut Chips, 4.5 Gram (About 2000pcs) 1x1mm Solder Chips Ultra Tiny Easy Solder Silver Solder Chips for Jewelry Making Jewelry Repair

How to Make Jewelry with Argentium Sterling Silver: Intro and Soldering Download, Jewelry, Jewelry Making Video Downloads

Types of Silver Solder in Jewelry - Halstead

Help with silver soldering. Making sure your solder stays put.